We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

User Guides

User Guides/Instructions

STORAGE OF TRANSFERS

Your waterslide transfers will last many years, if kept in the correct conditions. DO NOT store near heat, in direct sunlight or in cold temperatures. Ideal temperature is 17-20 degrees Celcius.

Storing transfers too hold, or too cold, is likely to make them brittle. If this happens transfers can be 'rescued' by brushing over the image area with a coat of clear varnish (RailMatch or Phoenix Precision ONLY). Leave to dry thoroughly and then soak in the usual way. PLEASE NOTE, the area of varnish will become outer edge of the transfer so try to paint over the image area only.

APPLICATION INSTRUCTIONS FOR WATERSLIDE TRANSFERS

Below are general instructions for Waterslide Transfer applications.

Fox Transfers have also developed a method of application particularly for difficult and complex transfers (especially linings) - so, you may also want to take a look at this method if you are not confident with the process. Click here for illustrated step-by-step guide for this alternative method.

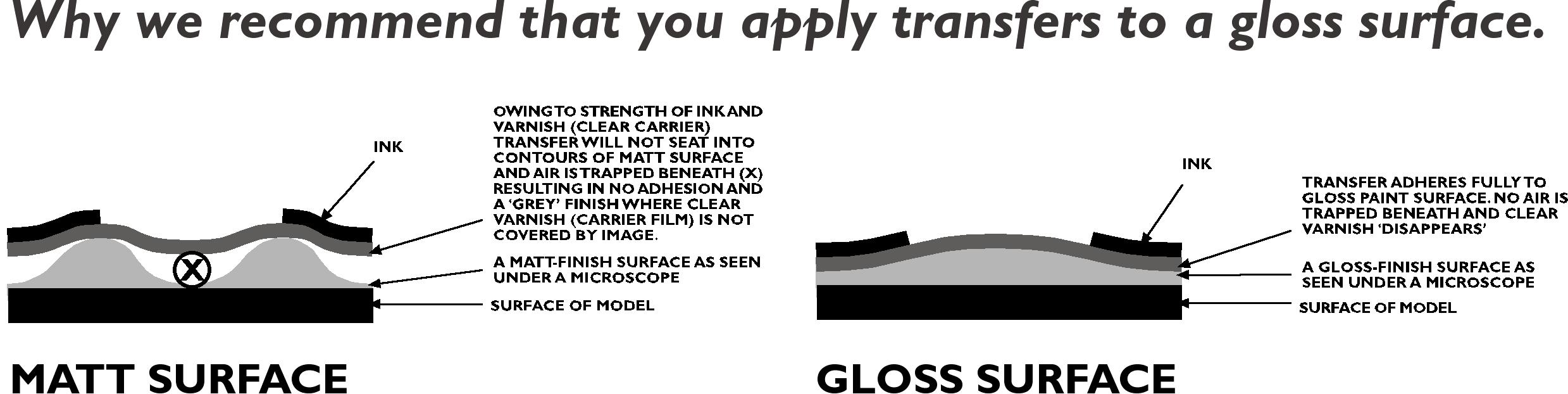

- Ensure the surface onto which you intend to apply the transfer is clean and grease-and dust-free. THE SURFACE SHOULD PREFERABLY BE OF A GLOSS FINISH. The more matt the finish, the less likely it is that successful adhesion will take place and the more likely it is that even the miniscule amount of carrier film will show up.

- Cut the transfer from the sheet, allowing a margin around the image. Do not cut into the printed image unless you are deliberately reducing the area of transfer to be applied, eg: cutting lining down to size either depthways or lengthways.

- Immerse the transfer in a saucer or trough of warm water for a few seconds. The container of water should preferably be large enough to accommodate the full, flat transfer. Owing to modified chemistry, we now recommend that you add a drop of washing up liquid to the warm water. The transfer will initially curl up, then partially flatten out. Test whether the transfer has become detached from the backing sheet by gentle pressure with a finger. The larger the transfer, the longer it will take to separate from the backing paper. Use hot water - not cold - and certainly not of boiling temperature.

- When separation has occurred, remove the transfer and the backing paper as one item, position in the required location retaining the image in position with light pressure whilst sliding out the backing paper and disposing.

- Make final adjustments to the position, at the same time dabbing off excess water with an absorbent cloth or blotting paper. Ensure there are no air- or water-bubbles trapped between transfer and location surface by gentle outward stroking of cloth or blotter to edges of transfer.

- Whilst the transfers are reasonably durable once cured, we would recommend (particularly if the model is going to be handled) that you over varnish the model after transfer application. Fox Transfers only recommend and sell either RailMatch or Phoenix Precision products for use with our Waterslide Transfers.

Guidelines

- Ensure that the transfer is properly soaked before you attempt to remove it from the backing paper. A simple test is to check that there is no ‘drag’ on the paper, and that the transfer slides off smoothly.

- Where, for instance, a long line of otherwise unsupported lettering is involved, slide the transfer backing paper in such a way that the transfer has to move the minimum distance, ie not lengthways. This will lessen the stress of the carrier film and reduce the likelihood of the transfer breaking up.

- The less handling and adjustment your transfer receives to position correctly, the better the adhesion is likely to be, and the less likely it is that damage will occur.

- In certain circumstances, you may find it necessary to manipulate a transfer for quite some time to obtain your desired position, eg. around small detail. This may involve the application of extra water to maintain the transfer’s mobility. To avoid over-diluting the adhesive on the back of the transfer, ensure that the small amount of extra water required has lain on scrap transfer backing paper prior to using it to further move the transfer.

- Allow to dry completely, preferably for several hours, eg: overnight. When all transfers have been applied and allowed to dry, Fox Transfers strongly recommend that a protective coat of a suitable varnish in gloss, satin or matt finish is applied over the transfer. This should be carried out particularly in circumstances where the transfer is positioned on an exterior surface, or where the model will be handled and DEFINITELY where the transfer is likely to come into contact with chemicals of any description, for example a carriage washing unit, where the cleaning agents employed have extremely deleterious effect on all transfers, paint and other surfaces.

Fox Specific Lining Sheets and Lining Transfers

Fox Transfers have also developed a method of application particularly for difficult and complex transfers (especially linings) - so, you may also want to take a look at this method if you are not confident with the process. Click here for illustrated step-by-step guide for this alternative method.

The transfers in these packs have been carefully prepared for you, following painstaking research into both the original vehicles and using the models or kits onto which they are likely to be applied.

It must be emphasized that application to your model of some of the elements - especially tender, cab and tank panels - is a task which requires a great deal of care and patience, but which if carried out correctly should give a far superior finish to your work.

We recommend initial marking-out of the extremities of each lining panel on your model, using either masking tape or a very faint blade mark with your craft knife or scalpel. Then cut the transfer panel about halfway along each side. Apply each section separately following the instructions on the transfer pack, only progressing to the next section when you are completely happy with the positioning of the one in hand. Butt-join each piece of transfer to the previous piece, ensuring no space is left between pieces and that they do not overlap.

We strongly recommend that ANY lining transfers are cut to a manageable length and joined using the method explained above. It is not advisable that you try to apply a full length of lining in one piece, this will not give a successful result (unless you are very experienced in applying these transfers).

REMEMBER

- THE BEST SURFACE FOR ADHESION OF TRANSFERS IS A GLOSS SURFACE. When the transfers have cured, you should over-varnish them for protection with a clear varnish of your choice - matt, satin (eggshell) or gloss.

- DO NOT TOUCH THE SURFACE OF THE MODEL WHERE YOU INTEND TO APPLY TRANSFERS. EVEN YOUR FINGERS CAN LEAVE GREASY DEPOSITS WHICH WILL IMPEDE SUCCESSFUL APPLICATION. Ensure the surface is dust and grease-free.

- DO NOT RUSH APPLICATION OF TRANSFERS. If you have spent weeks or months building your model - or even just re-painting it - it is unreasonable to expect to apply the transfers in a couple of hours. Your patience will be rewarded with a model you’ll be proud to exhibit.

APPLICATION INSTRUCTIONS FOR ETCHED NAMEPLATES

- Cut the plate from the supporting fret, where applicable, using a sharp craft knife, holding the plate to the cutting surface with one finger to prevent it springing away. Cut tab as close as possible to plate

- Holding plate between finger and thumb, gently remove balance of tab with a fine flat file.

- Lay your model on its side. Apply a small amount of varnish to the back of the plate (to match that of your model finish) and position correctly - apply a small amount of even pressure. Leave to dry for 24 hours before turning over the model and repeating the process. By using a varnish which matches your model, any surplus varnish will blend-in and disappear.

Alternative Method - Apply an extremely small amount of adhesive to the back of the plate – one of the ‘superglues’ or impact adhesive of your choice will be suitable. Do not apply adhesive near the edges of the plate. Remove excess adhesive before applying plate as this will squelch out around the edges when the plate is affixed. To prevent incorrect affixing or problems with excess adhesive, mask off the area around the intended location of the plate with a low-tack masking tape, leaving exposed an area the shape and size of the plate. Remove masking tape when adhesive has set. - When modeling modern image locomotives, ensure before affixing your plates that you know precisely where the plates should be affixed: some are in ‘mirror image’ position, some are in totally different positions to allow for engine room grilles and windows etc.

HEADBOARDS, COACHBOARDS AND TAILBOARDS

These plates are fully interchangeable and can be affixed to the model using BluTac.